OUTPUT

Hunston Scientific

9204 Centerway Road

Gaithersburg, MD 20879

info@hunstonscientific.com

D. L. Hunston, President

SELECTED ACCOMPLISHMENTS FROM RESEARCH

Developed and analyzed methods to evaluate macro-molecule, small-molecule binding in

biological systems that have heterogeneity and site-site interactions. Quantifying this behavior

is a key to understanding enzyme actions and other biochemical regulatory mechanisms

(references 85, 51, 38, 26, and 4).

Generated the first long-term, environmental, fatigue data on pultruded materials used for structural applications. Such

information is essential if composites are to be used in bridges and construction (references 186,183, and 173).

Demonstrated that coupling agents on glass fibers often perform as they do on flat glass surfaces. This means that much

of what is known about coupling agents from adhesion studies can be extended to composites (references 162, and 160).

Developed the generally accepted mechanism for toughening in rubber-modified epoxy systems. These materials are the

basis for most commercial structural adhesives (references 76, and 75).

Co-wrote and edited the most comprehensive review of process monitoring in the fabrication of polymer composites

(reference 125)

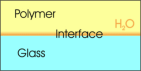

Quantify the high local concentration of water at a polymer-glass interface. This has

important implications for interface corrosion in such systems. (Reference 154).

Published the first comprehensive examination of linear viscoelasticity in a thermoset resin. The work demonstrates the

applicability of time-temperature superposition to some thermoset systems (reference (54).

Detail the critical structure-property relationships in rubber-toughened epoxies. This provides guidelines for the

development of better structural adhesives and composites (references 179, 175, 146, 120, and 100).

Demonstrated and modeled the rate and temperature dependence of mode-I fracture behavior in rubber-modified and

unmodified epoxies. This model makes possible the first meaningful comparison of inherent toughness in different resin

systems (reference 202, and 64).

Established the role of resin toughness in the mode-I delamination behavior of composites. This provided guidelines used

by many government and industrial organizations to optimize new composite materials (references 102, and 87).

Explained the rate and temperature effect in the mode-I fracture of structural adhesives. This resolved a long standing

controversy in the literature regarding the effect of loading rate (reference 113, 79, and 64).

Define the importance of time and strain rate in the elongational behavior of polymer solutions in converging and

diverging flows. This demonstrates the challenges for using nozzle geometries in the measurement of elongational viscosity

(reference 37).

Showed that glassy thermosets have high friction even when they are fluorinated so that the surface energy is equal to

PTFE. Demonstrate that surface energy and friction can be independently varied through the inclusion of additives. This

established the importance of molecular structure in the low friction of PTFE (reference 48).

Established guidelines for optimizing anomalous flow behavior, such as drag reduction, in dilute

solutions of high molecular weight polymers by showing the role of molecular weight distribution in efficiency and

demonstrated the importance of chemical as well as hydrodynamic forces in flow induced degradation (references 45, 30,

and 29).

OUTPUT

Hunston Scientific

9204 Centerway Rd., Gaithersburg, MD 20879

info@hunstonscientific.com

D. L. Hunston, President

Developed and analyzed methods to evaluate macro-molecule, small-

molecule binding in biological systems

(references 85, 51, 38, 26, and 4).

Generated the first long-term, environmental,

fatigue data on pultruded materials used for

structural applications (references 186,183, and 173).

Demonstrated that coupling agents on glass fibers often perform as they

do on flat glass surfaces (references 162, and 160).

Developed the generally accepted mechanism for toughening in rubber-

modified epoxy systems (references 76, and 75).

Co-wrote and edited the most comprehensive review of process

monitoring in the fabrication of polymer composites (reference 125)

Quantify the high local concentration of water at a polymer-glass

interface (Reference 154).

Published the first comprehensive

examination of linear viscoelasticity in a

thermoset resin (reference (54).

Detail the critical structure-property relationships in rubber-toughened

epoxies (references 179, 175, 146, 120, and 100).

Demonstrated and modeled the rate and temperature dependence of

mode-I fracture behavior in rubber-modified and unmodified epoxies

(reference 202, and 64).

Established the role of resin toughness in the mode-I delamination

behavior of composites (references 102, and 87).

Explained the rate and temperature effect in the mode-I fracture of

structural adhesives (reference 113, 79, and 64).

Define the importance of time and strain rate in the elongational

behavior of polymer solutions in converging and diverging flows

(reference 37).

Demonstrate that surface energy and friction can be independently

varied in a thermoset through the inclusion of additives (reference 48).

For dilute solutions of high molecular weight polymer solutions,

established the role of molecular weight

distribution and chemical nature in the efficiency

of anomalous flow behavior, such as drag

reduction, and flow induced degradation (references 45, 30, and 29).